Inspection & Reverse Engineering

Analysis and quality design

through precision measurement

analysis system

Hankook Precision Works maintains and manages the quality of all products according to a set of strict standards, has expertise, extensive skills, and the latest inspection/measurement equipment, to pursue our standards.

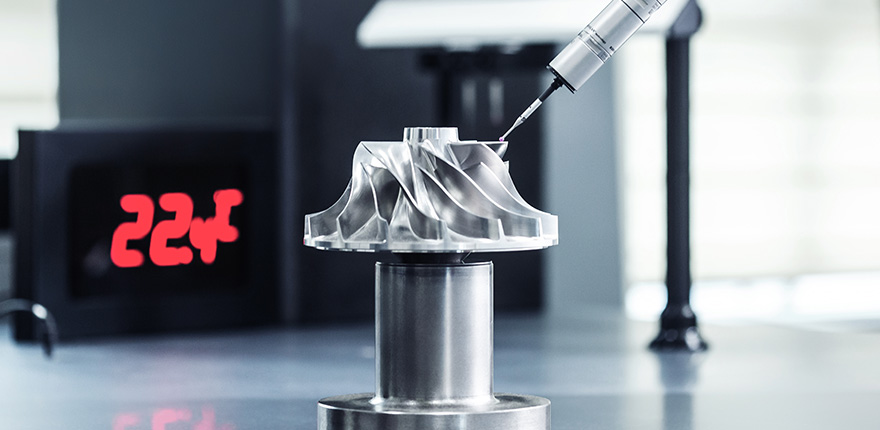

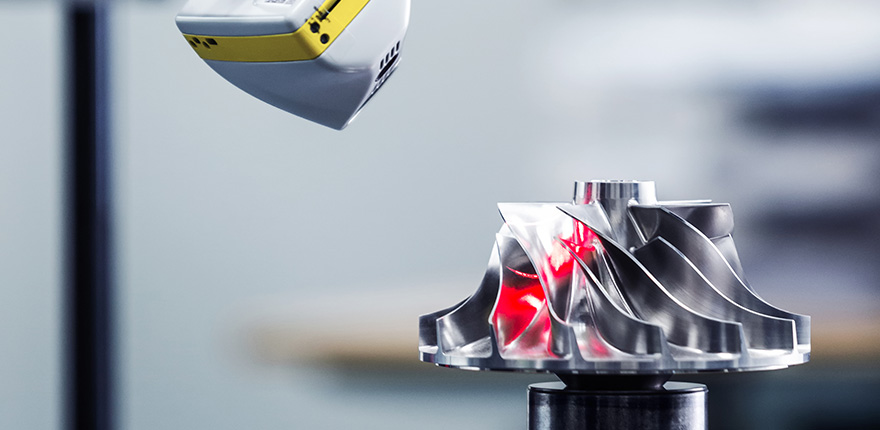

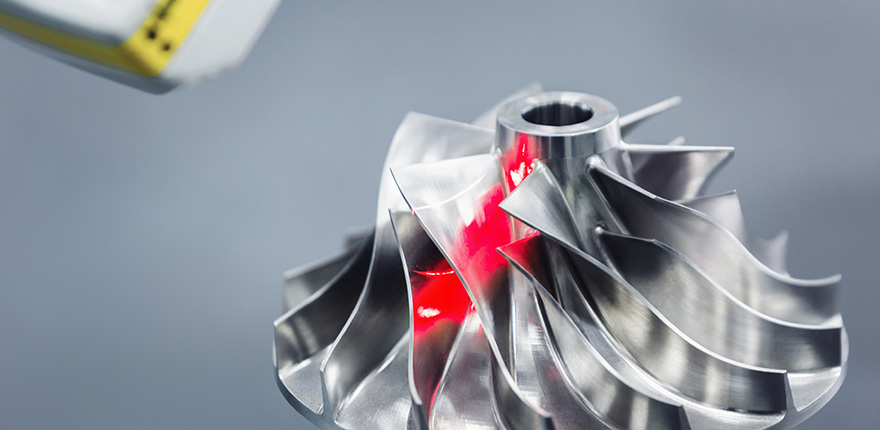

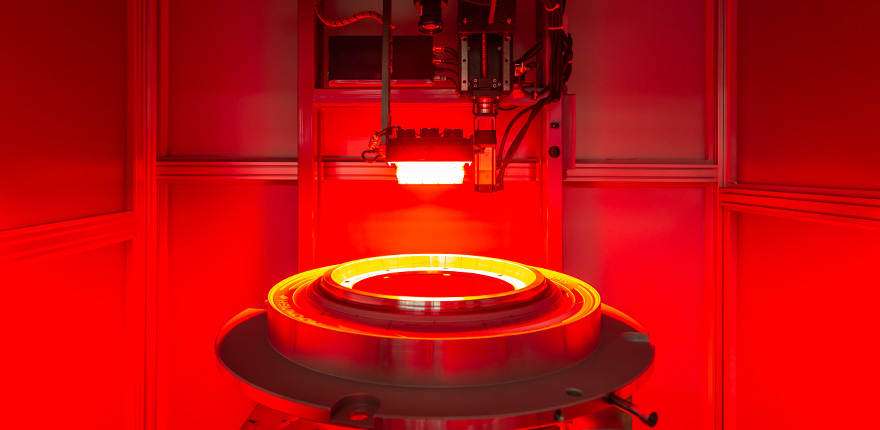

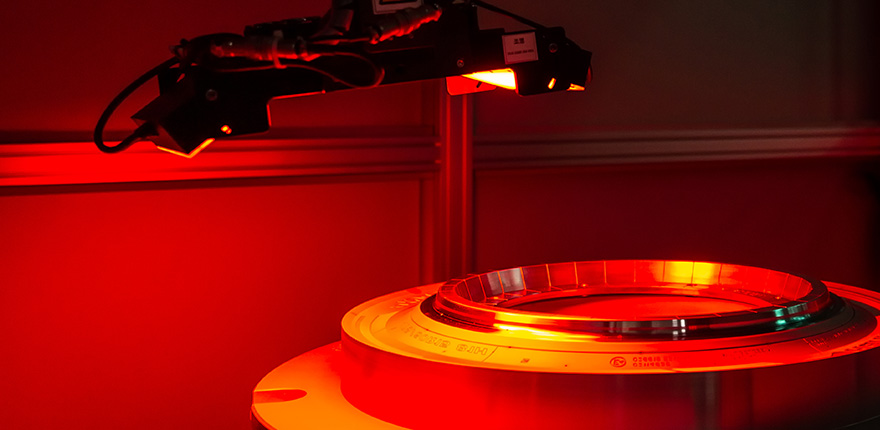

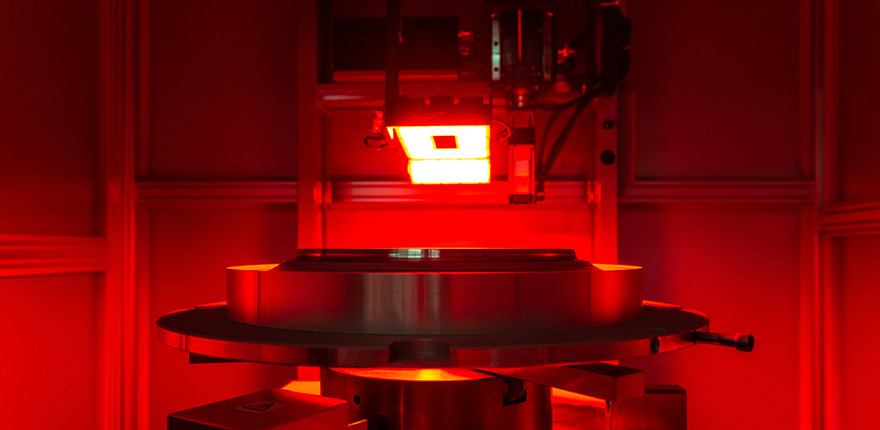

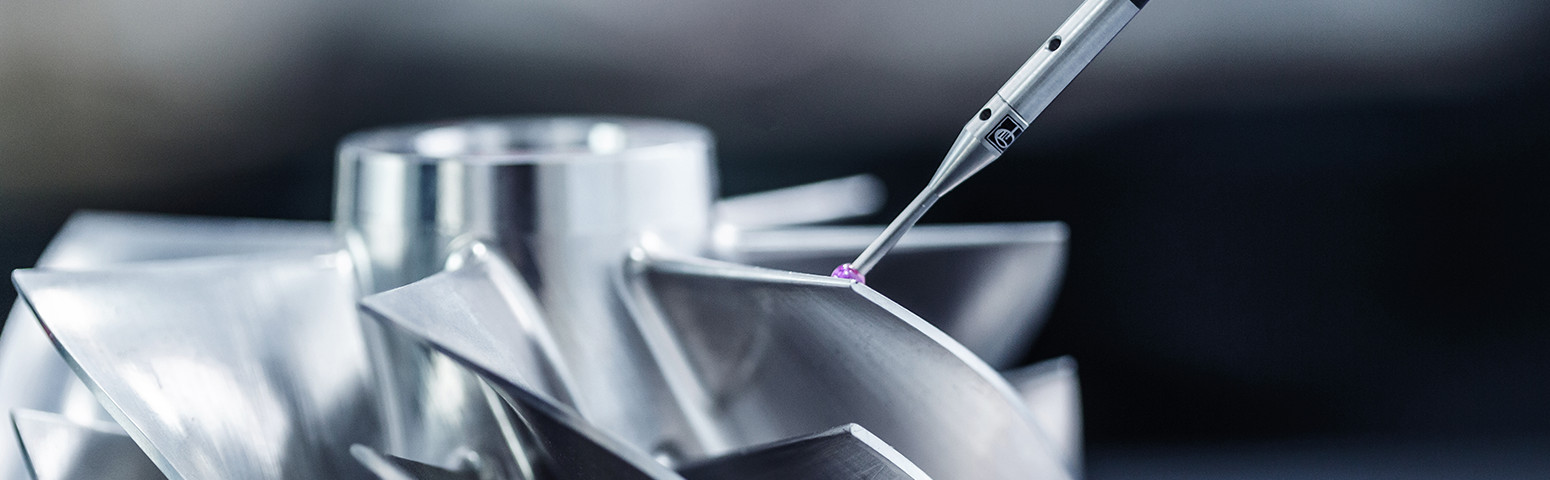

3D Precision Measurement

Hankook Precision Works has a three-dimensional measurement system that provides accurate 3D measurements and analysis for a wide range of customer needs.

We conduct measurements of tire shapes, deformation analysis, and reverse engineering using contact probes and contactless laser scannning.

- Data : 2016. 11 ~

- Measurable Range : 1,500 * 1,500 * 1,000mm

- Weight allowance : 2,500kg

- Measuring type : 3D Contact Method + Laser Scanning

- Software

- Neuro Measure : 3D Measuring Software

- Geomagic Control X : 3D Laser (Comparative Analysis)

- Geomagic Design : 3D Laser (Reverse Engineering)

- Nikon Laser Scanner (High precision 3D Measurement)

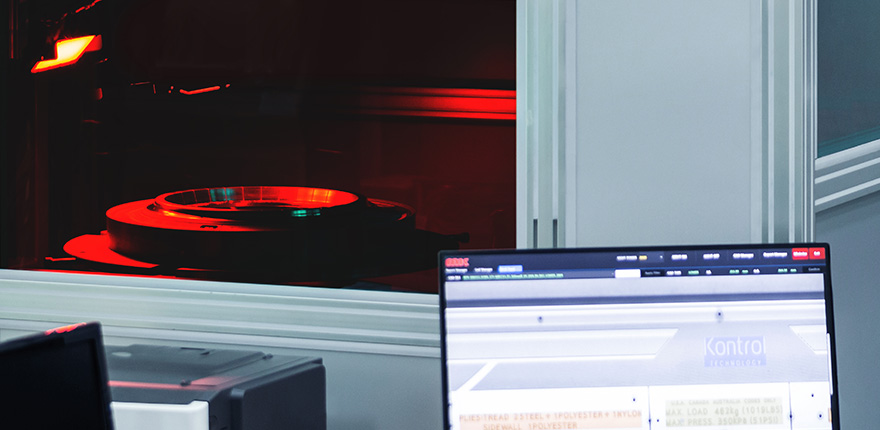

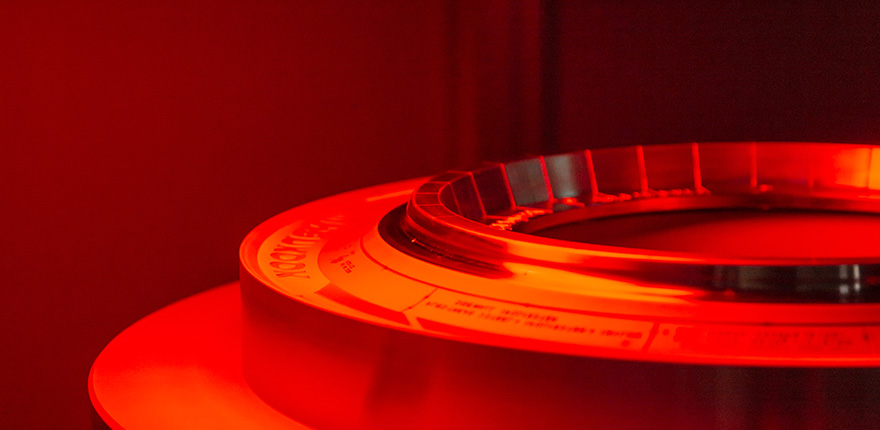

Side Mold Letter

& Image Scanning

In 2016, Hankook Precision Works adopted the side-mold letter & image scanning system for the first time in Korea.

By scanning the text and processing status of the Side Mold and comparing it to CAD data, we detect errors automatically and eliminated human error.

- Dev.Period : 2015. 01 ~ 2015. 08

- Mass Application : 2016. 11 ~

- Scanning Process

- CAD Data converts imagination data

- Letter Scanning (Auto)

- Each Item Group Box handling (Auto)

- Letter awareness / Letter Size Check (Auto checking)

- Printing Inspection Report

- Letter Awareness / Size Checking