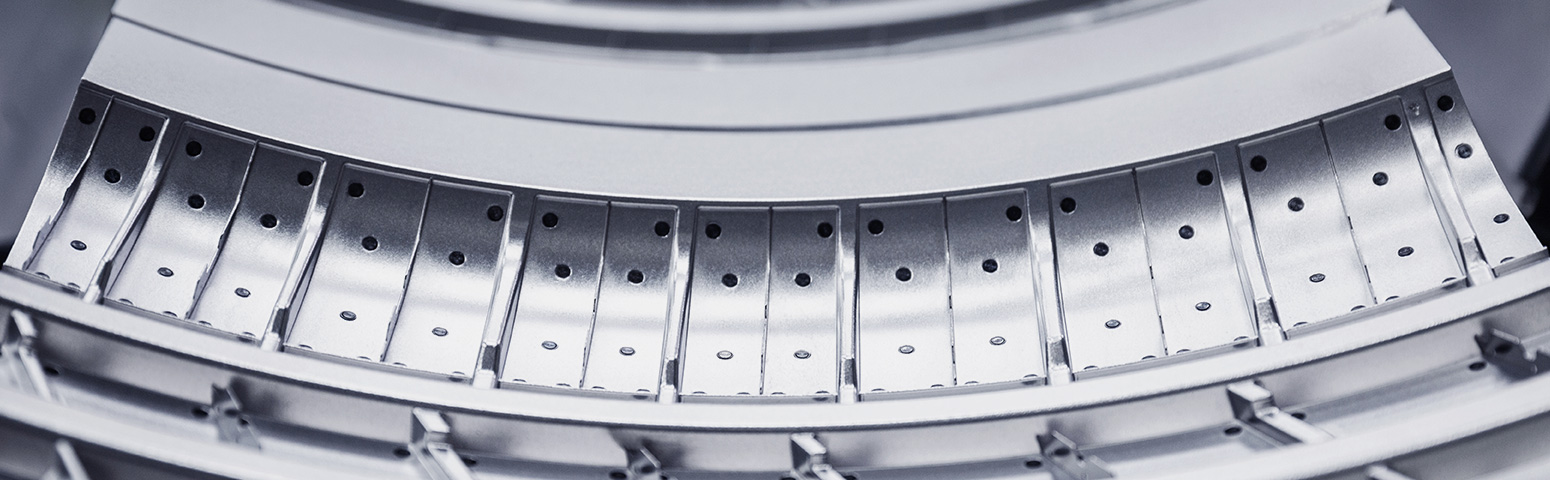

Tire Mold

Precision mold production through

5-axis machining and casting technologies

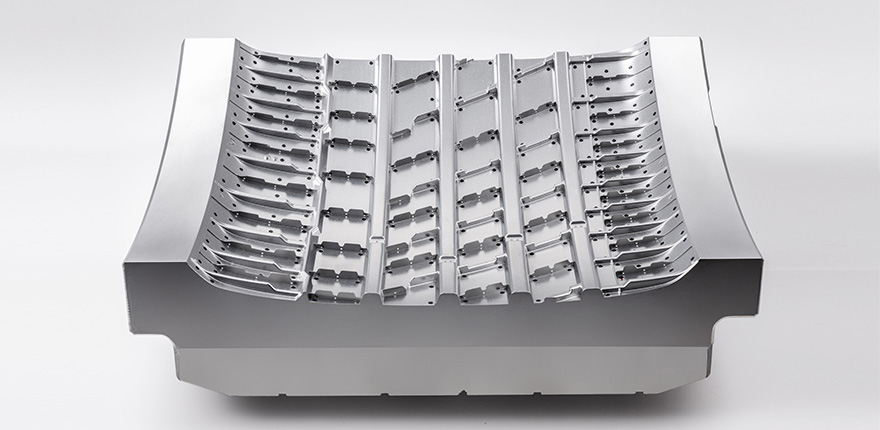

A tire mold is a precision mold that gives a tire its final shape. Hankook Precision Works produces tire molds of the highest quality with the 5-axis machining and casting technologies that enable the precision mold production. Depending on the use and purpose of the tire, we provide both conventional molds and new type molds of various technologies and forms, such as casting mold, direct engraving mold, ventless mold, and wave parting mold.

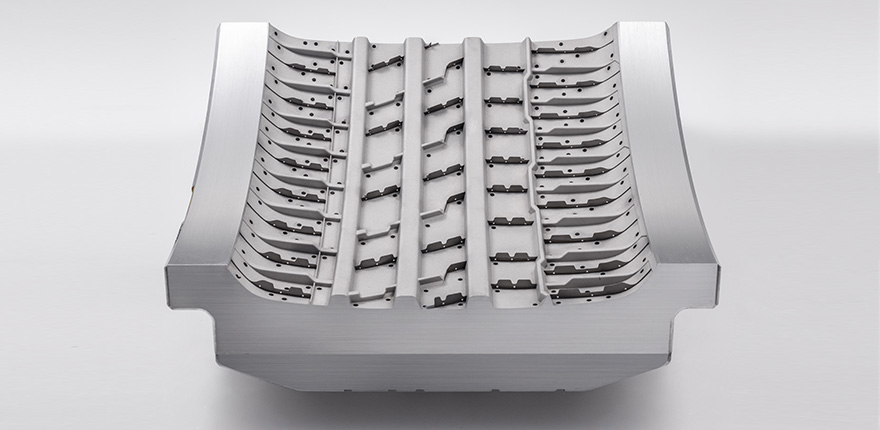

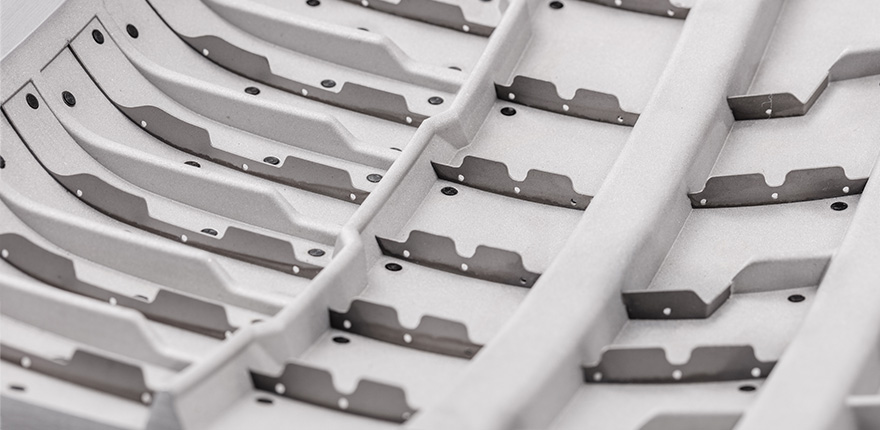

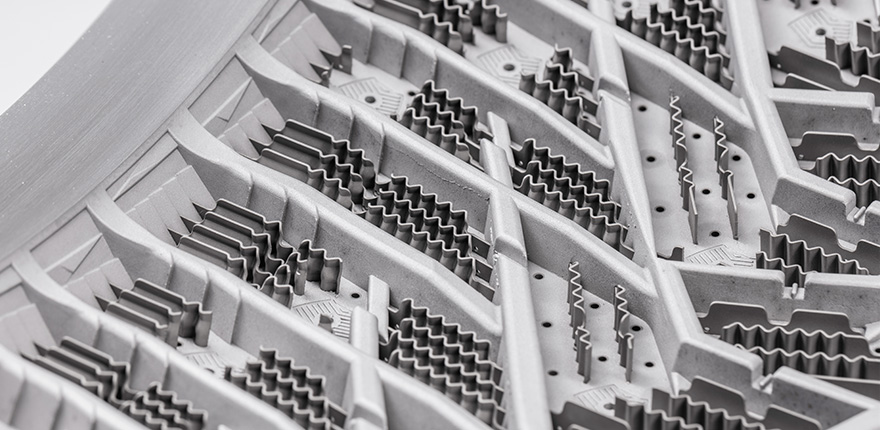

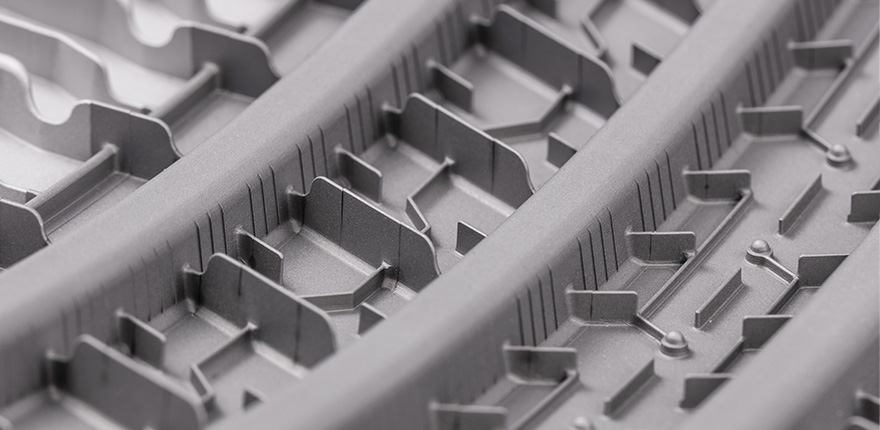

Engraving Mold

An engraving mold is manufactured directly from aluminium raw materials applying ultra-precision 5-axis machining technology. It features high precision and short manufacturing time. Hankook Precision Works has the most optimized processing condition with specialized CAD and CAM technologies.

Casting Mold

A casting mold is manufactured with precision casting technology, which is useful to realize complex Tire patterns and various forms of tire Molds. Hankook Precision Works manufactures Casting Molds of the best quality with the combination of specialized Precision Casting, CAD and CAM technologies.

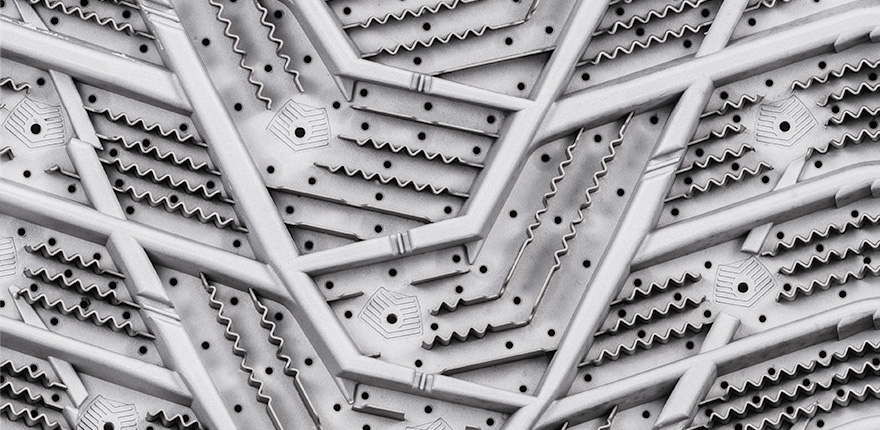

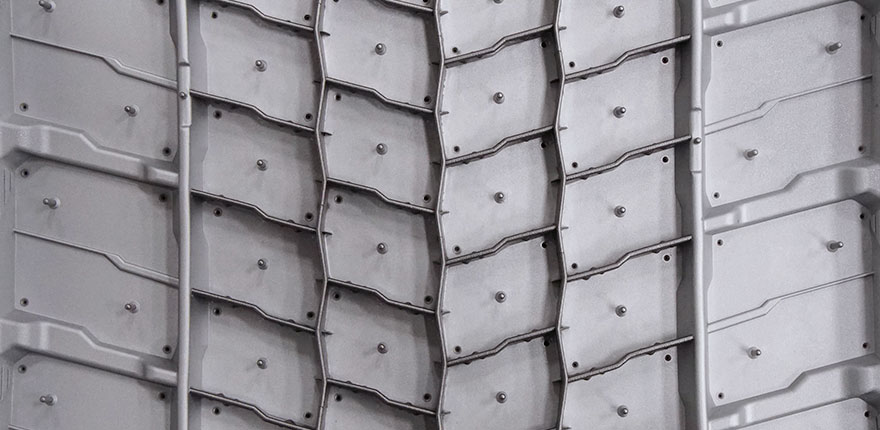

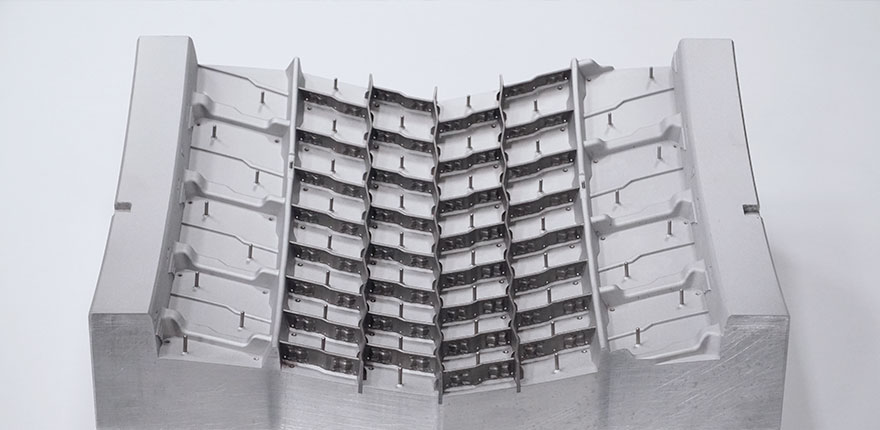

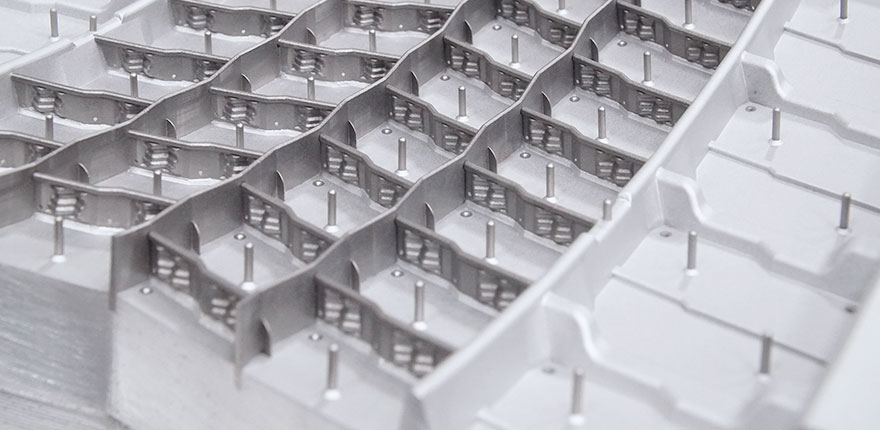

Puzzle Mold

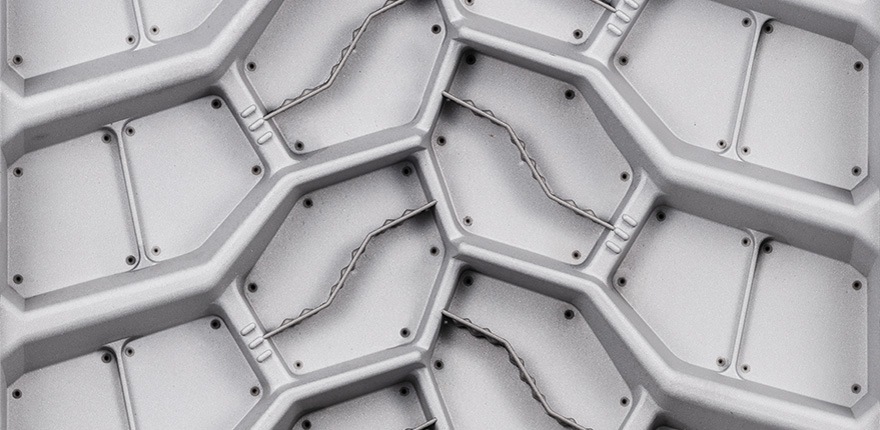

Puzzle mold is a new mold type that replaces the air holes of exiting tire molds with the small gaps between inner pitches. It does not leave any bent rubber, and therefore, improves the exterior quality of the tire as well as shortening the time for tire manufacturing processes.

Hankook Precision Works features the metal molding technology that can design and manufacture the puzzle mold.

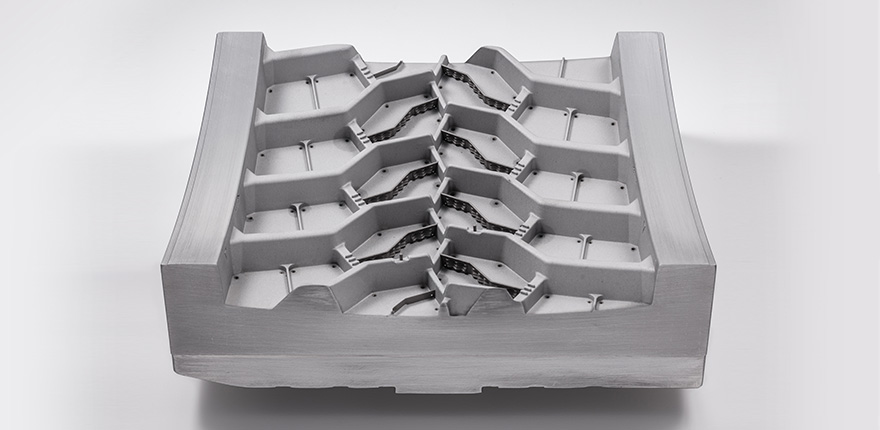

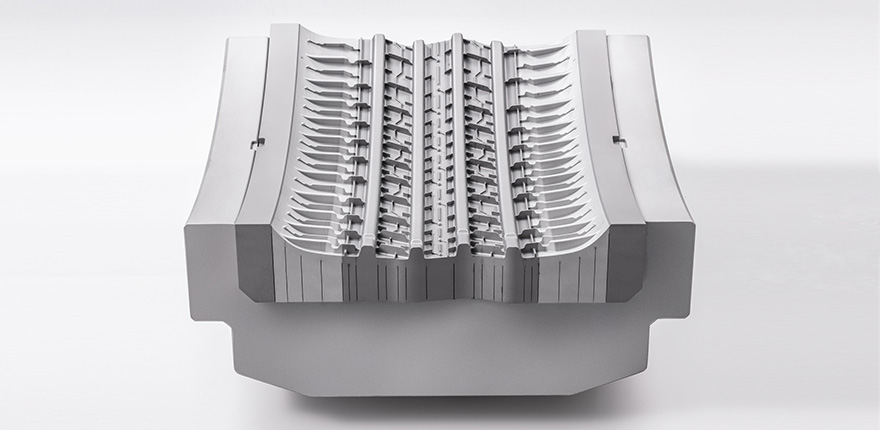

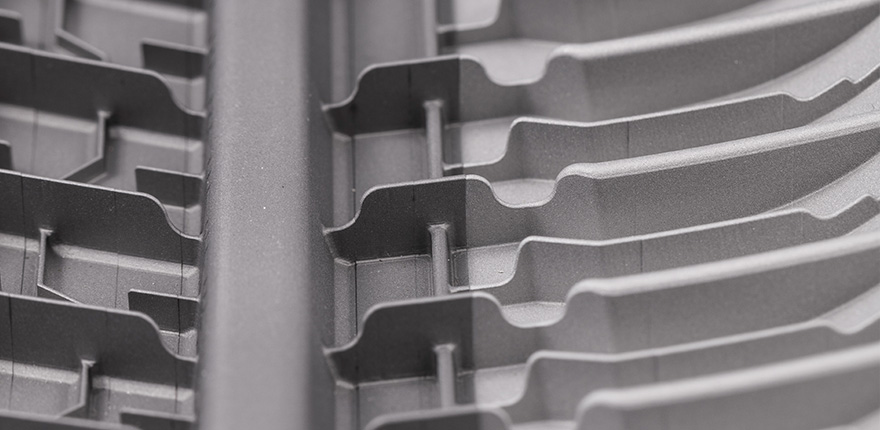

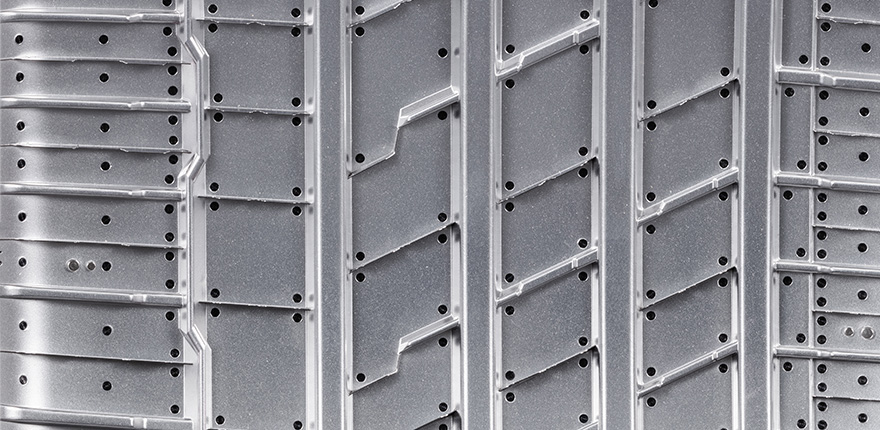

Wave Parting Mold

A wave parting mold maintains the complex and diverse pattern forms of a tire as much as possible. It is very effective for improving the performance and exterior quality of a tire.

Hankook Precision Works features technologies for designing and manufacturing the wave parting mold.

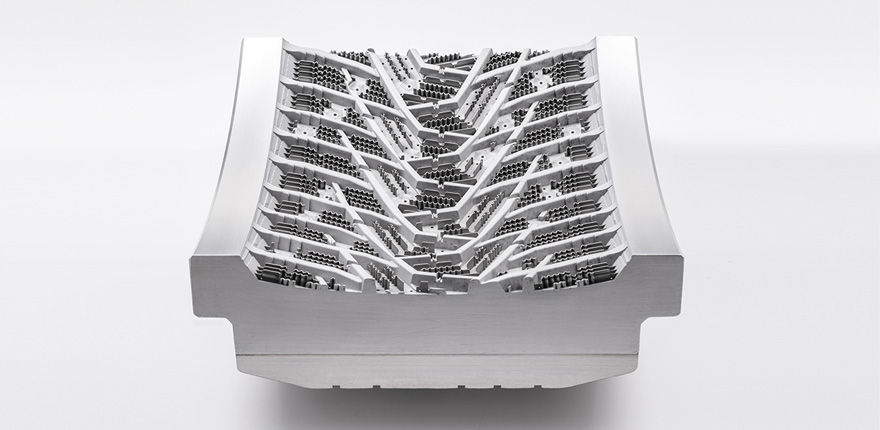

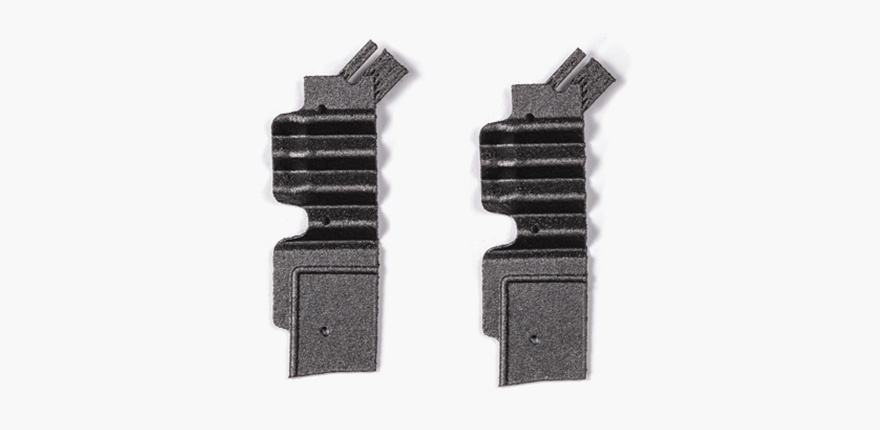

3D Printing Mold Parts

Using our metal 3D printer, we manufacture sipes and other parts for tire molds. Through process innovation, we are continuously achieving innovation by greatly reducing the manufacturing time for tire sipes and the processing time for mold parts of complex forms.

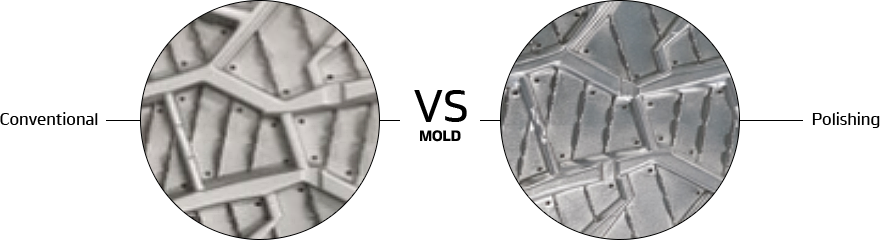

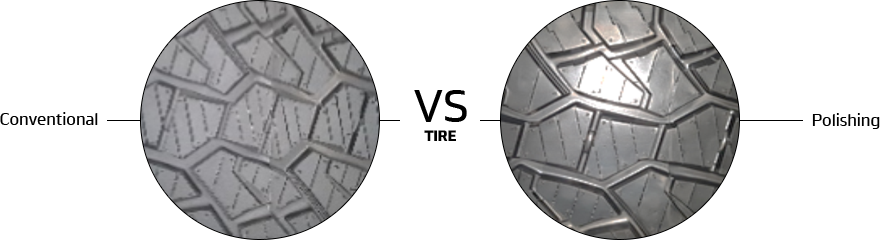

Polishing Mold

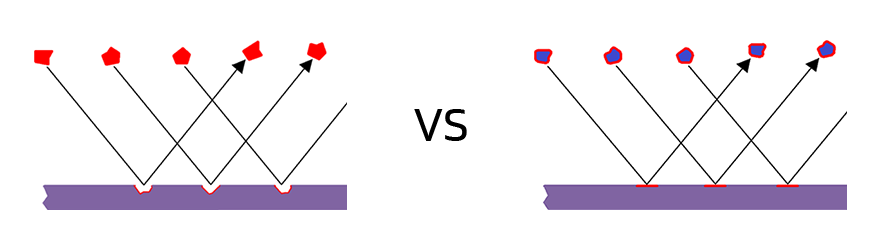

A polishing mold gets semi-permanent gloss on the surface by spraying silicon-carbide powder over without leaving any damage on it.

It improves the surface roughness of the tire mold, accordingly, making the tire exterior equivalent to that of a global top-tier tire manufacturer.

Development of semi-permanent technology for mold quality improvement

Improved exterior quality and image that are equivalent to that of a global tire manufacturer

Non-damaging abrasive technology on the mold surface

- Regular (Ceramic, Zircon, etc.)

- Polishing (Elastic Abrasive)