Precision Parts

Production of core products through ultra-precision machining in the field of aircraft and turbo machine

In 2001, we launched the precision parts business for aircraft and turbo machinery, utilizing our extensive infrastructure for software, precision processing machineries, and constant-temperature control system as well as the key technologies acquired from our tire-mold business. Since then, Hankook Precision Works has continuously accumulated technologies and know-hows through development and mass-production of core parts for turbo machineries and the development of precision parts for National R&D Institute. We aim to fully utilize new technologies such as metal 3D printing, precision laser processing and more, to expand our ultra-precision processing business for medical equipment, electric cars, autonomous cars, and more.

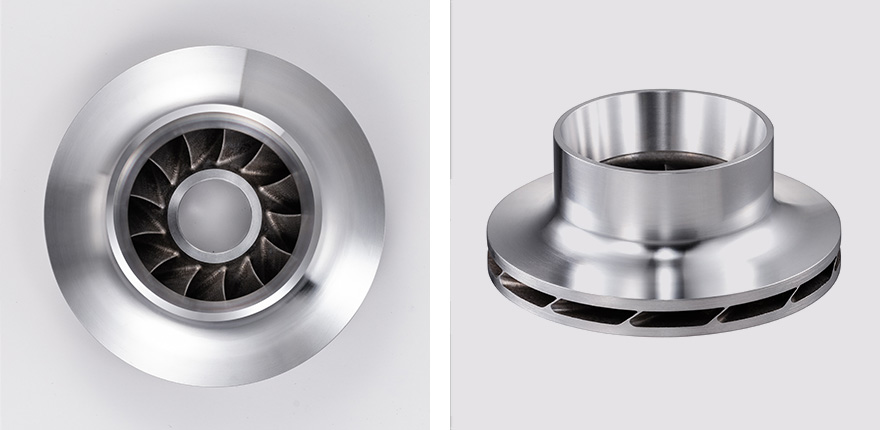

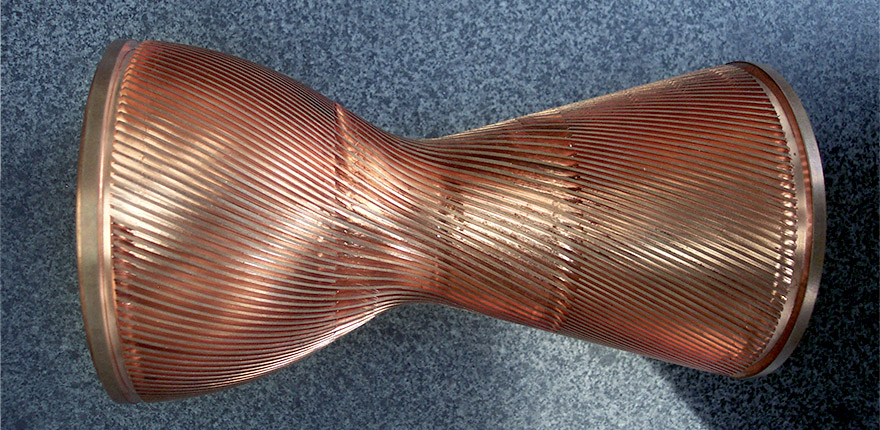

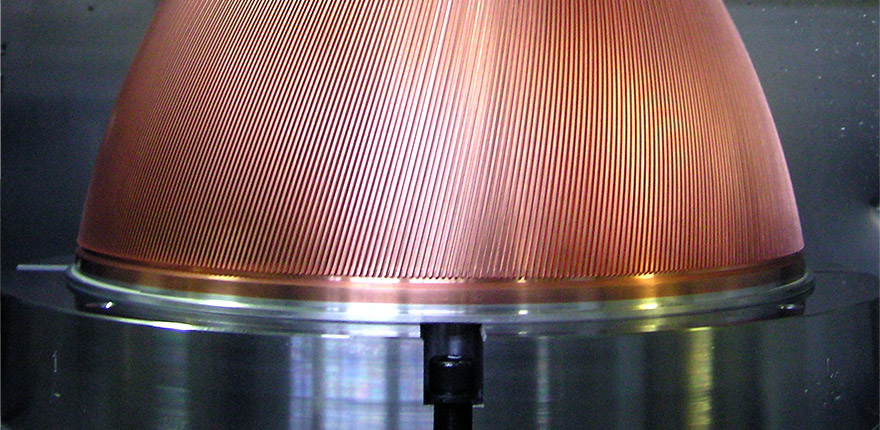

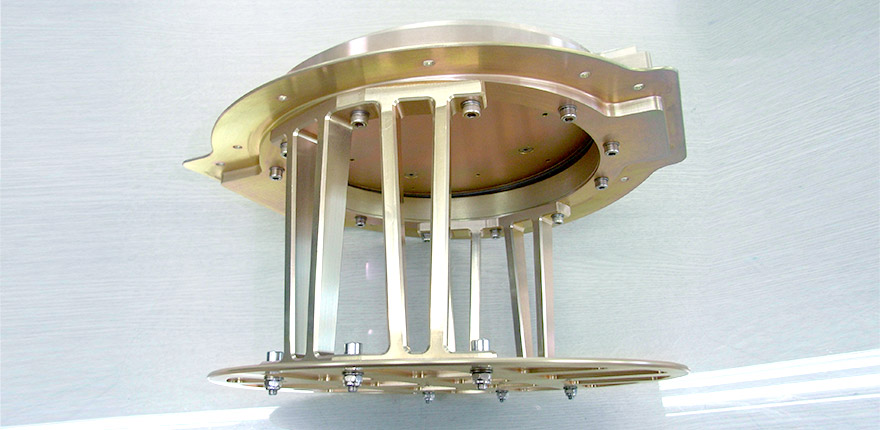

Turbo Machinery

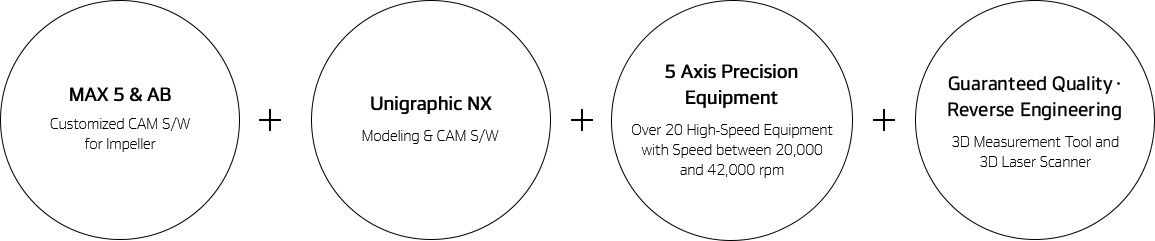

Using the customized software for impellers, we can produce parts of any form by designing the processing

steps independently.

We provide a total solution from designing to manufacturing and guaranteed quality with our high-precision reverse engineering technology and quality inspection using 3D laser scanner.

Products

- Regular Turbo Compressor

- Micro Turbo Compressor

- Turbo Refrigerant Compressor

- Turbo Pumps

- Turbo Charger

- Turbo Blower Impeller and Related Parts

Main Clients

- LG Electronics

- Korea Institute of Machinery and Materials(KIMM)

- Korea Aerospace Research Institute(KARI)

- Century

- Shinsung Engineering

- Hanon Systems

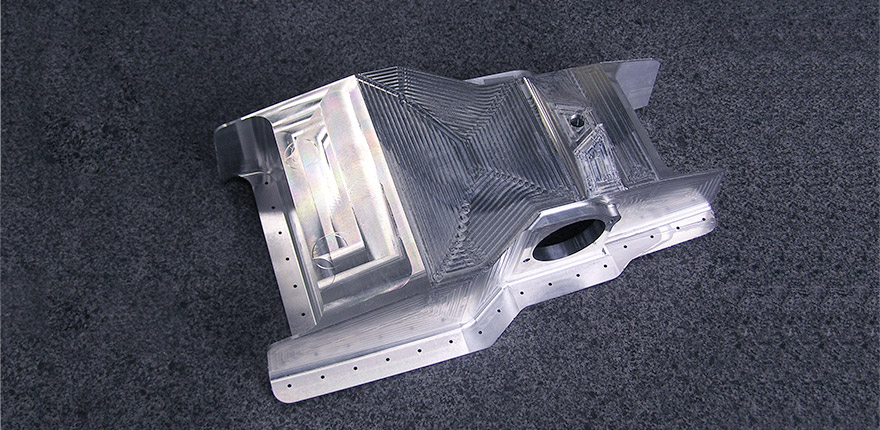

Aerospace

The core parts of aircrafts, satellites and gas turbine engines are ultra-precision processing products that do not allow even the smallest errors.

Hankook Precision Works has the best reverse engineering and quality inspection capabilities using 3D measurement tools and 3D scanners.

Products

- Airframe Parts for Aircrafts(Unmanned Aircraft)

- Airframe Parts for Satellites

- Research Equipment

- Parts Production for Local Manufacturing(Reverse Engineering)

Main Clients

- Korea Aerospace Industries(KAI)

- Korean Air(KAL)

- Korea Aerospace Research Institute(KARI)